SCHWEISSEN & SCHNEIDEN 2017

Thank you to all ProArc visitors during the 16th ESSEN SHOW in Düsseldorf, Germany - the most important cutting and welding fair in the world. We are very excited about a large number of clients stopped by our booth. In five days’ show, over 500 guests from over 60 countries had visited ProArc booth.

ProArc had participated for the 6TH time and demonstrated our latest products including:

• Research and Development

• Quality

• Performance

• Technical service support

You are welcome to see ProArc full product range from our website.

Top 3 inquiry in Essen, Germany

A lot of visitors have shown great interests particularly in below 3 products:

We invite you to take advantage of our very competitive pricing and first-rate service.

What’s new! ProArc Master series with XPR300 plasma system

ProArc’s Master cutting machine integrated with new EDGE Connect CNC and XPR300’s new ETHERCAT, allowing real-time data transfer between cutting motion and cutting process. In addition to all these great features, XPR300 comes with intuitive operating interface and wifi-communication for multiple systems online monitoring.

The new Hypertherm XPR300 plasma system, with its X-DefinitionTM technology, offers numerous advances in cutting process that include reduced bevel angle, shiner cutting surface in aluminum/stainless steel process that rivals laser cutting, 15% faster cutting speed on thick material, 40% more consumable life, 20% thicker piercing capability on stainless steel, 30% thicker piercing capability on mild steel, with 50% less operation cost!

Welcome your inquiry!

Drill more using Drill+ gantry with servo drive and CTS spindle

Drill+ gantry series is ideal for a wide variety of drilling applications including structural steel, general steel fabrication, bridge construction & infrastructure engineering.

Nowadays, it’s easy to see manufacturers have made the switch from radial drilling to CNC plate drilling. Benefits include the elimination of secondary processes, higher production efficiency and reduction of part cost and finishing time.

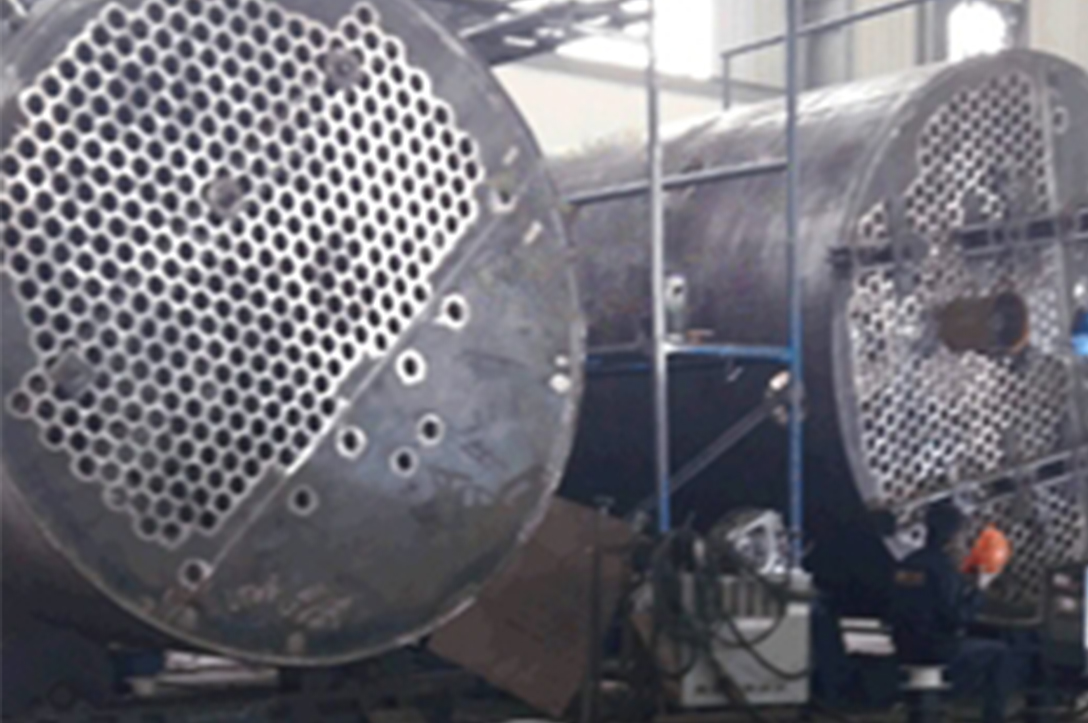

ProArc is happy to have delivered Drill+45 with DS-080 servo spindle (capacity: Ø6~80 mm) to our overseas customer recently - see left photo. Table size fitted is 3700mmW x 4000mmL that simply suits their max. plate size Ø3500 mm.

Drill with more ease and optimize your drilling operation!