『Mark your Calendar and be Our Guest in Düsseldorf』

SCHWEISSEN & SCHNEIDEN 2017 will be held at Düsseldorf’s exhibition center for one time only!

ProArc is back and participating the 6TH time.

– it’s the crossroad to see current developments & innovations

– the place to experience the latest trends that continue to drive our industry into the future

Be there and meet our experienced team.

Make plans and arrange your itinerary now. Please contact us if you need assistance.

『Take Your Welding Process to the Next Level with CW-218』

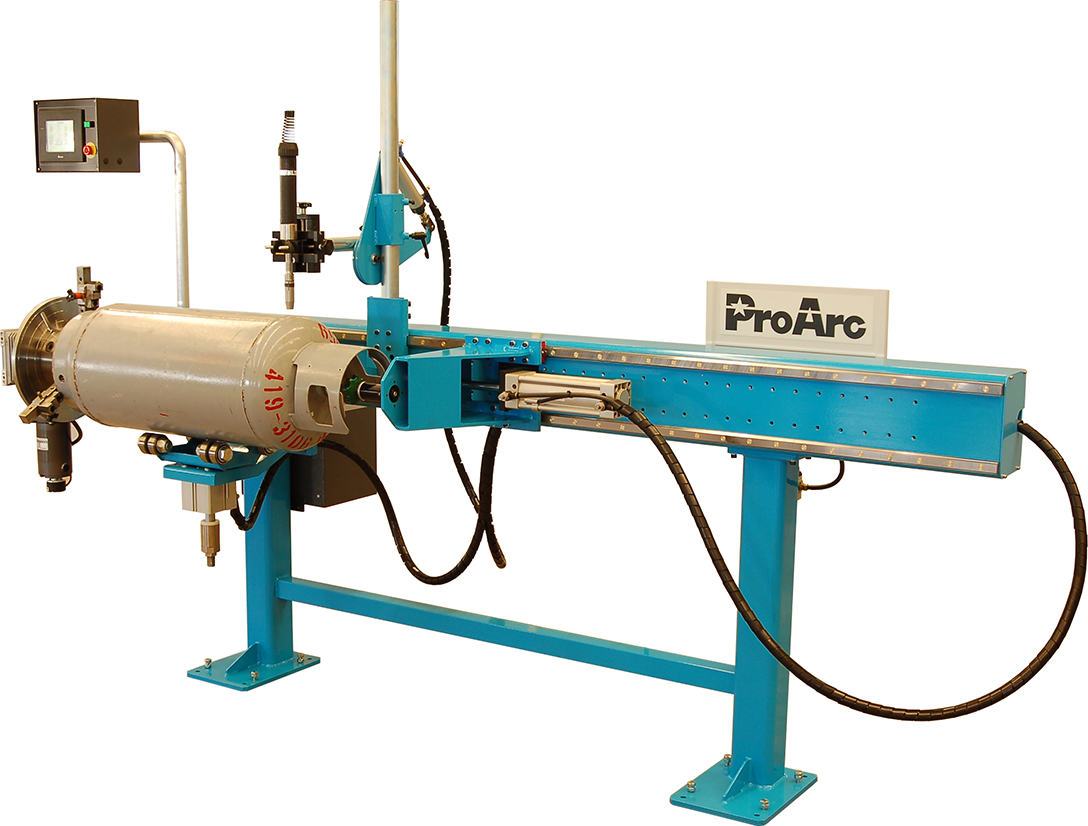

This system is designed for TIG, MIG or Plasma circumferential welding process. Model CW-218 is available to load the tank with 200 kilograms and 1,800mm long. The machine consists of powered headstock & pneumatic clamping tailstock for precise welding requirement.

Controlled by digital & PLC, it further achieves superior performance like no other system. The torch stand and tailstock are installed on rigid linear guideway & runner block for operator’s easy adjustment. The new completed CW-218 was dispatched to a manufacturer of water, air and fuel tanks for trucks.

Other common/similar welding job such as solar water tank, LPG cylinder, storage tank…etc. are available as well.

『Achieve Accurate Filler Metal with ProArc Cold Wire Feeder on Seamwelder』

Adding cut length filler rod to the weld puddle is labor intensive, expensive and wasteful. The TIG Cold Wire Feeder uses standard "spooled" wire which eliminates stub loss associated with standard TIG cut length rod, efficiently increases arc time, and increases productivity.

ProArc WF-10 cold wire feeders are designed to supply filler metal into the weld puddle during GTAW or PAW.

ProArc Longitudinal Seamer is integrated with servo drive system and smart control HMI. We set all welding process in the controller to improve the welding performance.

Besides stable feeding speed, intuitive operation HMI and pulse synchronous lock function, there is an important good reason to install ProArc WF-10 cold wire feeder on ProArc seamer system integration – i.e., we can connect two control boxes very easy then set up the WF-10 cold wire feeder become one of parameters of seamer welding processes by one click.

Don’t miss the opportunity to upgrade your seamer production line - Call us!

『ProArc your Single Source Supplier』