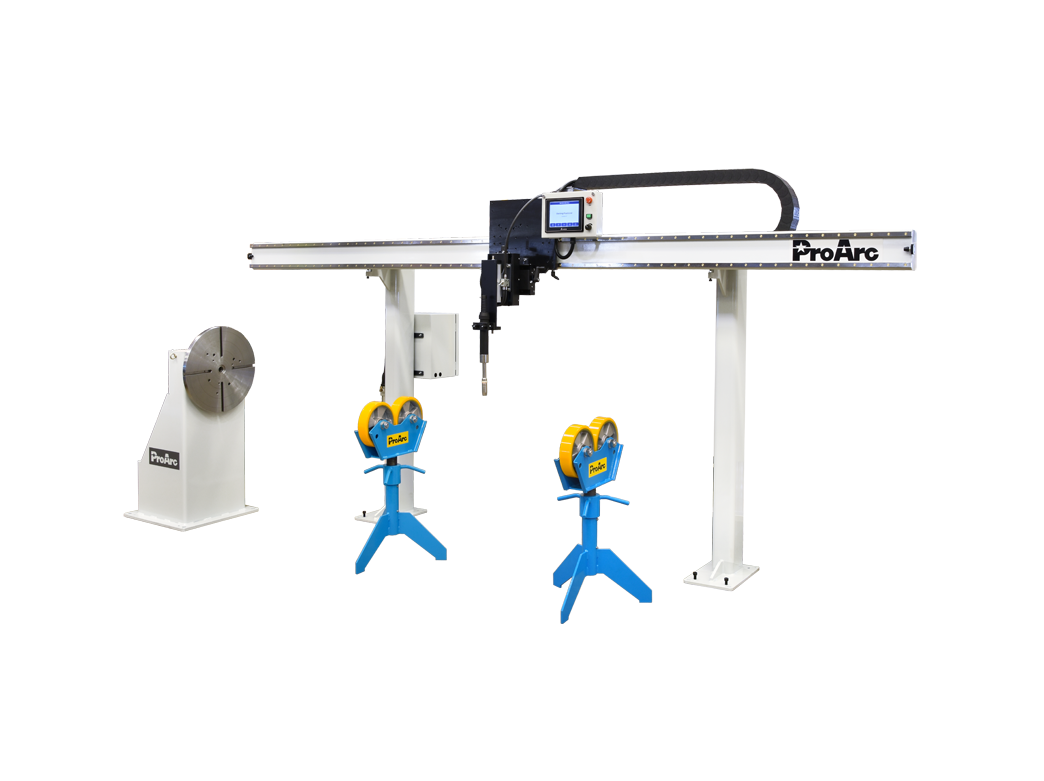

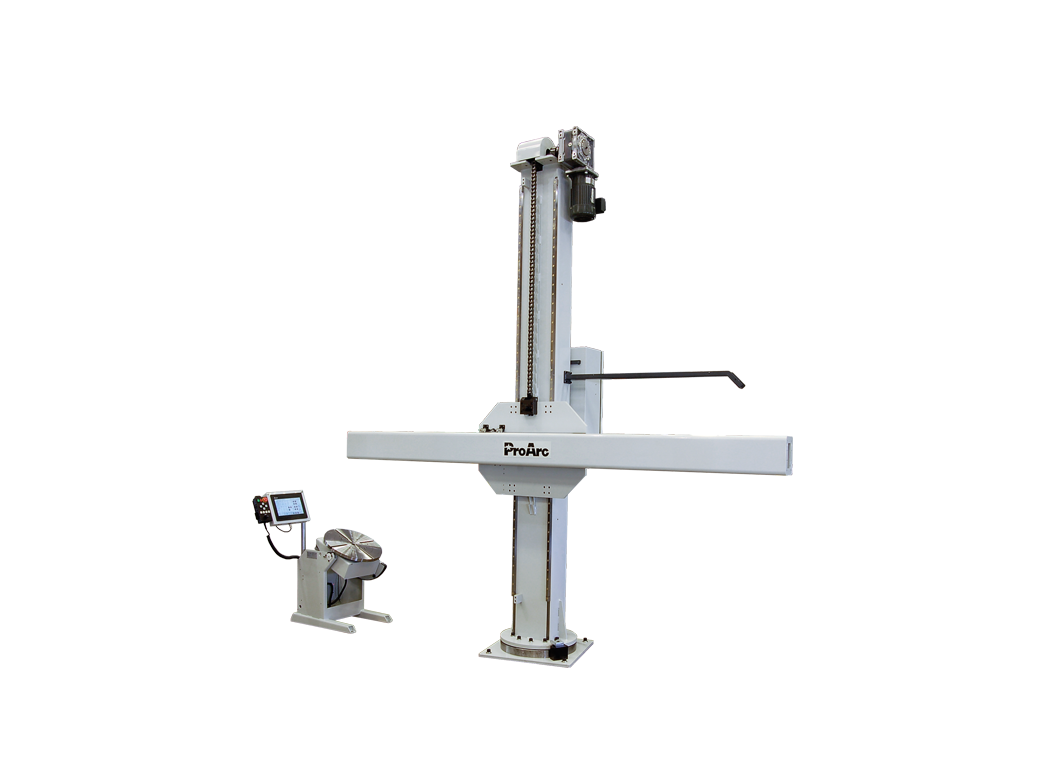

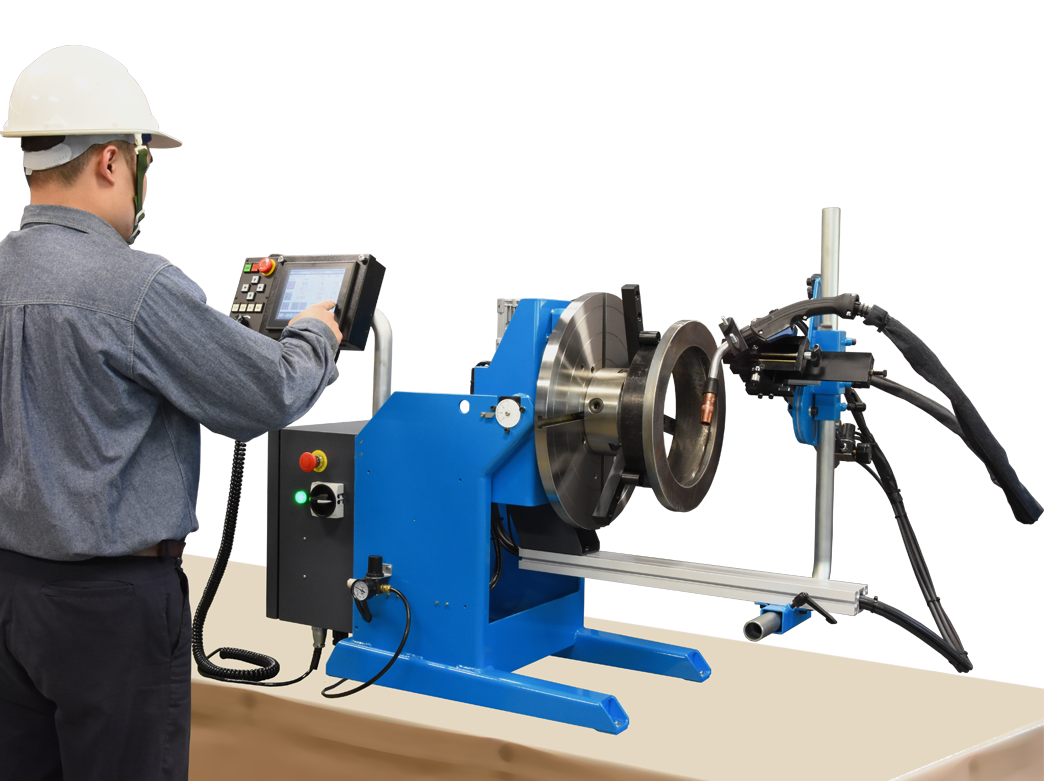

ServoArc welding automation package

ServoArc welding package can be simply applied in ProArc standard welding product by changing servo motor and integrate with advanced control box CB-500 or CB-600. 4 major advantages you will get: 1. Equipped with servo motor 2. Welding program can be edited and stored 3. 0~10V analog interface available to control welding current 4. 3 additional dry contacts available for accessories such as Cold Wire Feeder, Arc Voltage control, Welding Oscillator etc.