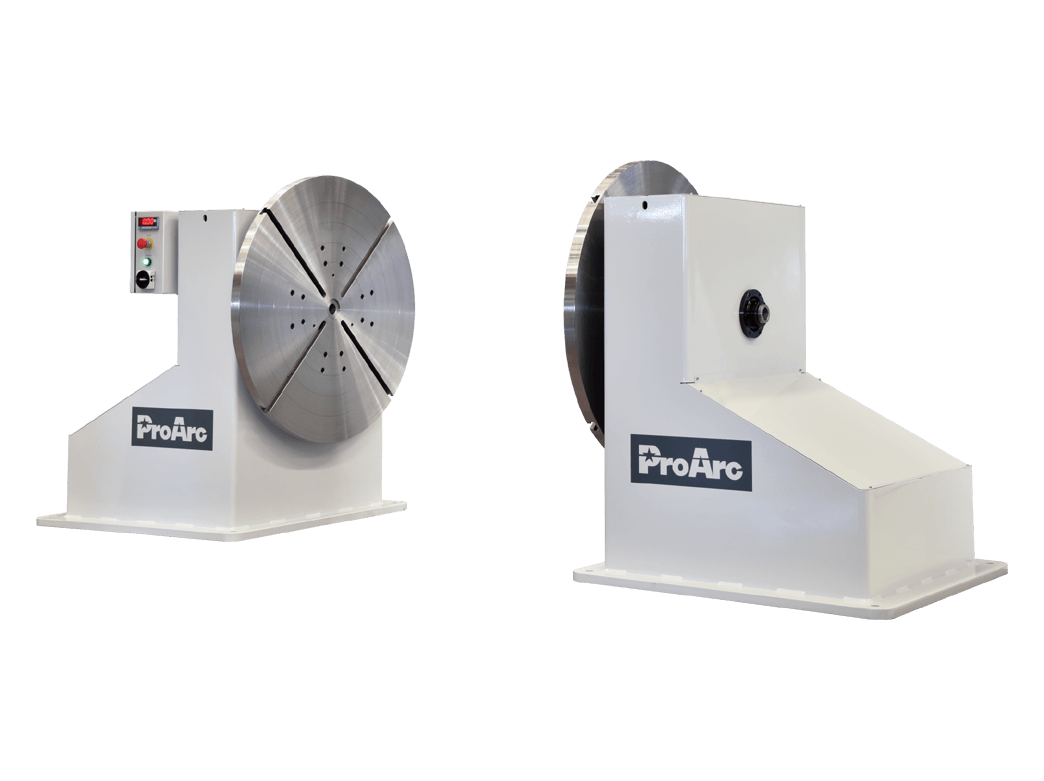

Model

Unit

HTS-1000

HTS-2000

HTS-4000

HTS-6000

Power input

AC 100 ~ 240V, 50/60Hz, 1 phase

AC 220V, 50/60Hz, 1 phase

AC 220V, 50/60Hz, 1 phase

AC 220V, 50/60Hz, 3 phase

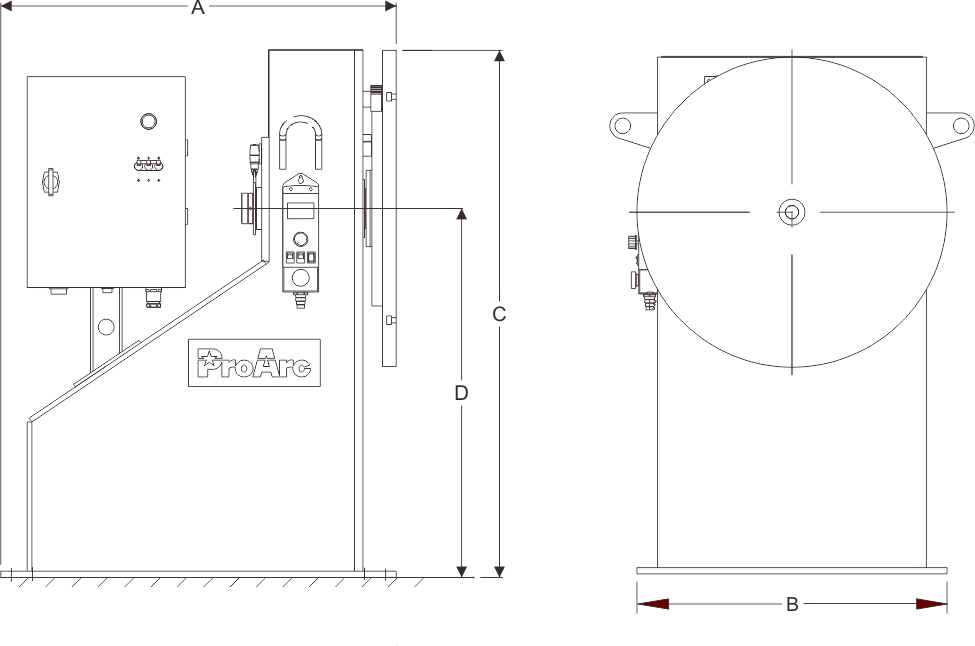

Overall length (A)

mm

510

750

900

1,000

Overall width (B)

mm

500

600

1,000

1,100

Overall height (C)

mm

825

1,000

1,175

1,300

Center to floor (D)

mm

600

700

800

800

Total loading capacity

kg

1,000

2,000

4,000

6,000

Rated eccentricity

mm

100

200

300

200

Eccentric load torque rating

kg-cm

5,000

20,000

60,000

60,000

Table dimension

mm

450

600

800

1,000

Through hole

mm

Ø25

Ø26

Ø35

Ø40

Table pilot hole

mm

Ø50 x 5

Ø50 x 5

Ø50 x 5

Ø75 x 5

Table slot bolt size

M12

M12

M16

M20

Rotation speed

rmp

0.12 ~ 2

0.05 ~ 1

0.05 ~ 0.8

0.05 ~ 0.8

Earthing

amp

300

300

600

600

Model

Unit

HTS-10K

HTS-15K

HTS-20K

Power input

AC 220V, 50/60Hz, 3 phase

AC 220V, 50/60Hz, 3 phase

AC 220V, 50/60Hz, 3 phase

Overall length (A)

mm

1,150

1,350

1,350

Overall width (B)

mm

1,200

1,500

1,500

Overall height (C)

mm

1,600

2,000

2,000

Center to floor (D)

mm

1,000

1,250

1,250

Total loading capacity

kg

10,000

15,000

20,000

Rated center of gravity

mm

200

300

300

Eccentric load torque rating

kg-cm

100,000

225,000

300,000

Table dimension

mm

1,200

1,500 x 1,500

1,500 x 1,500

Through hole

mm

Ø40

Ø50

Ø50

Table pilot hole

mm

Ø75 x 5

Ø100 x 5

Ø100 x 5

Table slot bolt size

M24

M30

M30

Rotation speed

rpm

0.04 ~ 0.8

0.02 ~ 0.5

0.01 ~ 0.25

Earthing

amp

600

1,200

1,200

※ Different voltage available depends on request