|

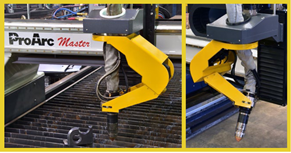

Precision and accuracy are the two main factors that determine the quality of our finished bevel products. ProArc new plasma bevel head enables precise bevel cuts within an angular range from +50° to -50°. High acceleration ±720° rotation enables to use machine at maximum efficiency. Torch height is controlled automatically with analogue arc voltage to an accuracy of ±0.05 mm, so part accuracy is maintained throughout the cut. |

|

Key factors - 34% reduction in volume - 50% higher responding speed - 0.1° positioning accuracy - 0.05mm torch height control accuracy |

|

|

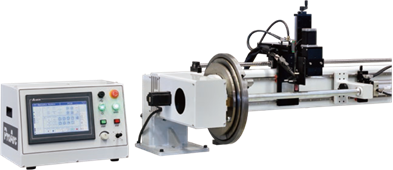

The PCW-350 precision welding lathe provides highly repeatable weld results with extremely consistent welding speed and minimal run out. It is specifically designed for precision welding and enable horizontal or vertical configuration with no extra parts required. Working length 600mm and 1,200mm is its standard. PCW-350 is specifically designed for welding a wide range of circumferential parts and components for aerospace, medical, food industry …etc. The smart controller offers fully control of positioning, speed, moving distance, welding current, welding sequence and AVC. The AVC with torch retract function allows precise tungsten to work gap setting for precise welding. |

|

Key factors - Smart and friendly controller - 0.02~50rpm rotation speed - 0.05mm positioning accuracy - 40mm through hole for shielding gas |

|

|

Applications - Circumferential welds retract function allows precise tungsten to work gap setting for precise welding. - Longitudinal welds - Cladding the outside of a part - Welding - MIG, TIG, Micro plasma, Laser - Cladding - MIG, TIG, Laser |